Our Services

- Shutdown inspection of boiler.

- Boiler performance improvement.

- Trouble shooting for boiler problems.

- Providing onsite training to operating peoples.

- Study for operating alternative fuels.

- 100% petcoke firing in existing boiler.

- Field quality auditing.

Shutdown inspection of boiler:

Inspection of boilers in shutdown condition and the suggestion will be given to increase the life, availability and performance of the boiler.

- Measuring thickness of pressure parts.

- Complete inspection of pressure parts in flue gas side and water/steam side.

- Complete inspection of non-pressure parts.

- Review of old operating log sheets for improvement.

Boiler performance improvement:

Performance study is focused to increase the combustion efficiency and auxiliary power reduction by tuning the operational parameters.

- Calculating the direct and indirect efficiency of boiler with respect to fuel fired.

- Calculating air requirement for better combustion with respect to the operating fuel.

- Gas analysis to monitor the combustion status.

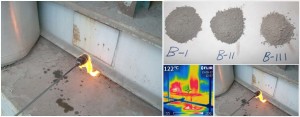

- Thermography survey to calculate the heat loss due to poor insulation/ refractory.

- Calculating the efficiency of the pumps, fans, cooling towers etc…

Trouble shooting for boiler problems:

Study will be conducted depends upon the problem list given by the customer. The problems like tube failures, high operating bed temperature, heat exchanger vibration, low steam temperature, water carryover, more unburnt, low fan performance, high auxiliary consumption etc will be studied and suggestion will be given to avoid recurrence.

Providing onsite training to operating peoples:

We provide onsite training to the operating peoples which enhance their operating and analytical skills. Class room training will be conducted using power point presentation. Also field training will be given as per the requirement.

Study for operating alternative fuels:

Study will be conducted based on the type of boiler and the type of fuel going to be used. During the study we will focus on the capacity requirement of other auxiliaries like fans and pressure part heat transfer area requirement and bed fluidization velocity etc…

100% petcoke firing in existing boiler:

Increasing in coal price and its low calorific value tends the power plant sector to switch over to petcoke firing in their existing boiler. We had wide experience in running petcoke in the existing boiler without doing any major modification.

Field quality auditing:

The main purpose of auditing is to ensure the boiler parts and its auxiliaries were erected as per the design requirement. If actual erection varies from design requirement then it will create impact on performance and availability of the plant.